CerFil R&D project

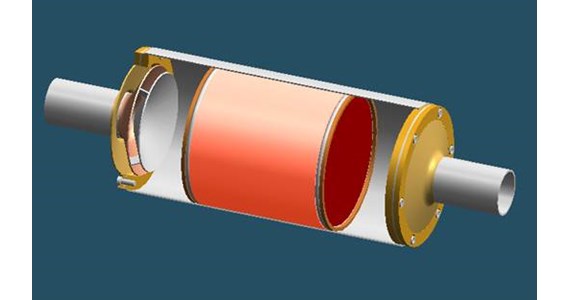

A Silicon Carbide (SiC) based extruded monolithic filter, with very high collection efficiency (>99%) for nano-sized particles featuring low pressure drop and high material reliability.

A two layer gradient filter structure (a filter membrane with an overlaid highly porous "foamy" layer) functions at the same time as a fine particle separator and as a soot oxidation reactor, through a catalytic coating dispersed into the entire ceramic microstructure. Advanced catalytic coatings for soot oxidation incorporated into the filter microstructure. Two types of novel catalytic coatings will be developed: Physical Vapour Deposition (PVD)-based nano-scale catalysts and Supported Liquid Phase (SLP) catalysts. Adaptive control of flow direction in the ceramic filter based on comprehensive computer modelling tools, extended beyond the state-of-the-art for the design and optimisation of soot particle filter systems. The project is structured around four work packages: filter development, development of catalytic coatings, testing and characterisation, and modelling and simulation.

Partners:

- Per Stobbe at NoTox A/S, Denmark

- AACHEN UNIVERSITY OF TECHNOLOGY, Germany

- AEA TECHNOLOGY PLC, United Kingdom

- ARISTOTLE UNIVERSITY OF THESSALONIKI, Greece

- CENTRO RICERCHE FIAT S.C.P.A., Italy

- FEV MOTORENTECHNIK GMBH, Germany

- JOHNSON MATTHEY PLC, United Kingdom

- Technische Universiteit Delft, The Netherlands

Title: “Functionalized ceramic membrane filter for highly efficient soot particle removal”

The CerFil research project was sponsored by the EU commission under FP4 BRITE/EURAM

Start date: 1998-07-01 End date: 2001-06-30