Catalyst coating of Silicon Carbide monoliths

Coating of DPF - Diesel-Particle-Filters with catalytically active coatings is used to lower the carbon oxidation temperatures. The non-oxide ceramic Silicon Carbide (SiC) exhibit properties very different from oxide ceramic monolith materials. Stobbe Tech A/S gained over 20 years’ work and experience in producing Silicon Carbide WFF (Wall-Flow-Filters) with pore size: 5, 15, 25, 35 and 100 µm and cell density ranging 10 to 200 CPSI (Cells-per-Square-Inch).

The important pore range developed by Stobbe Tech A/S, are created during the extrusion process, (before the firing process) giving advantages such as:

- lower cost of raw materials

- pore size easier selectable

- pore size distribution very narrow

- no loss of pores under firing

- no dead-end pores created during firing

Wash coat

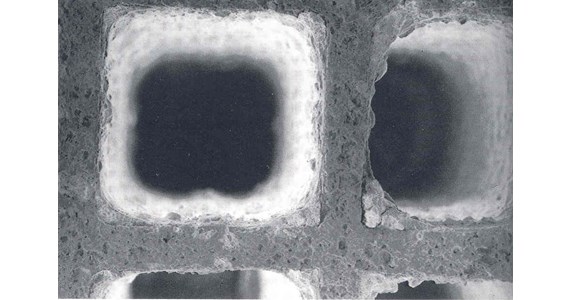

A good gaseous phase oxidation catalyst is dependent on wash coat thickness often in the range of 20-60 µm, porosity, surface, etc.. Wash coating the Cordierite flow-through monolith wall surface will block most of the pores causing no problems for the oxidation catalyst system. Wash coating a Wall Flow Filter is a challenge as blocking or decreasing the size of the important filtrating pores will increase the monolith pressure drop.

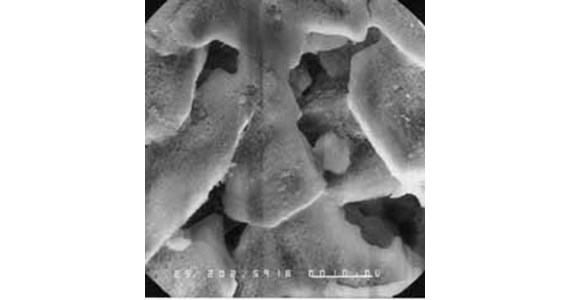

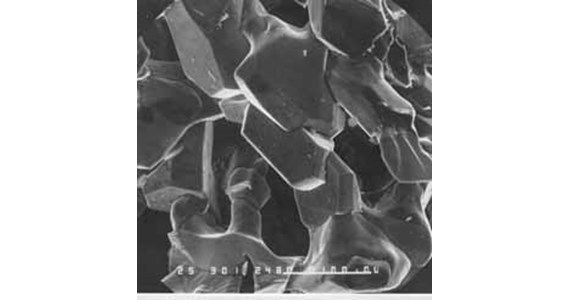

Left - Material F-940 magnified 2,000 times showing a thin well anchored oxide wash coating. The bar is 10 µm long. Middle - SEM photo showing the raw, clean non coated porous wall magnified 300 times. The bar is 100 µm long.

Regeneration temperature of the soot oxidation catalyst coated WFF is very much dependent on the effective contact area of the catalyst, the soot particle size and composition. We believe considerable contact area improvement is possible. This improved contact area will also have an effect on nano-size diesel engine soot particle separation, collection.

Experience

Preliminary experiments performed by Stobbe Tech A/S are with two kinds of wash-coat, Al2O3 based and ZrO2-Al2O3-SiO2 compound. Both showed very good adhesion to the SiC substrate under stationary condition as well as after exposure to large thermal shocks (cooling in water from 650 °C). It is considered to be an advantage that SiC has a coefficient of thermal expansion of about 4.6*10-6/°C which is closer to the value of Al2O3 (CTE is 7*10-6/°C) and the value for Mullite (CTE is 5.5*10-6/°C). Cordierite CTE value is close to 1*10-6/°C.

SiC oxide layers

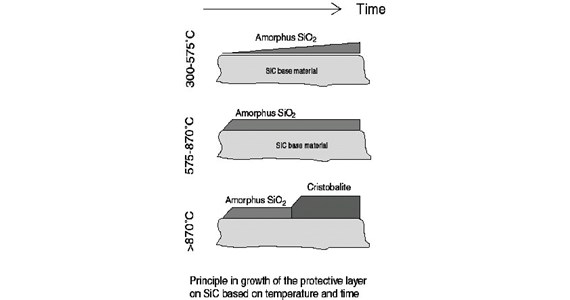

Below 500°C the created protective SiO2 oxide layer is very thin and amorphous. This phase will crystallize as Cristobalite or Tridymite between 700 and 800°C depending on the water vapor pressure. After formation of <15 nm layer SiO2 the oxidation rate drops rapidly if the temperature is kept below 850°C. The layer increase is in effect zero after a few hours. Above 850°C the oxidation increases somewhat with increasing temperatures until above 1,650°C where the oxide layer will start to decompose. If the oxide layer is formed above approximately 870°C the surface will appear "spongy-like" with increased surface area. The layer thickness is usually below 100 nm.

Firing

All SiC monoliths are fired at temperatures above 2,500°C in protecting atmosphere. Hereafter all monoliths are preheated to >1,000°C in oxidizing atmosphere for improved corrosion resistance and removal of residual Carbon. Hereby a >50 nm thick oxide layer is created which is suitable as anchor for the wash coat. The SiO2 layer can only be removed by dipping the structure in a 15% solution of HF and HNO3. Not recommended!

© Copyright 1997 - Stobbe