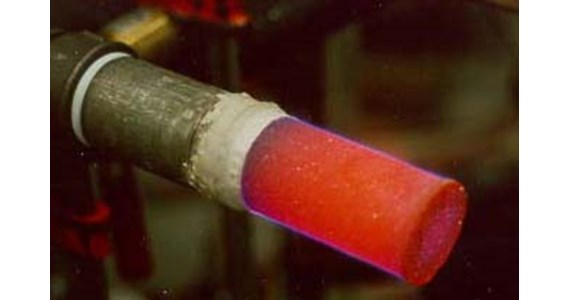

Pre-mix gas burner

Developed in 1988

Pre-mixed natural gas burner featuring no flames is created. The "relatively" low surface temperature around 1100 °C and therefore very low NOx emission levels.

Pre-mixed natural gas radiant burner head for power output exceeding MW/m². Compared to ordinary "hole-burners" the NOx outlet is reduced with a factor of 10.

When it comes to lower emissions and controllability of combustion, ceramic foam burners offer unprecedented advantages: excellent control of combustion parameters, high radiation efficiency and the ability to withstand extremely high temperatures. Ceramic foam burners can be used in all flat flame premix burner installations. One-on-one replacement of existing products is virtually always possible. Maximum environmental temperature is as high as 1.150 ºC. Not only that, ceramic foam is thermo shock resistant. Ceramic foam burners have unique insulating properties. Noise problems are reduced to a minimum as a result of the random structure of the material. The radiant heat is transferred to the product in a wide spectrum. The burner can be modulated to operate at an extremely wide range: the turndown ratio of the ceramic material is as high as 1 in 20.

60 mm extruded ReSiC tubes 1989

That means continuously variable from 100 kW/m2 to 2.000 kW/m2! In the range from 100 to 600 kW/m2 the burner operates in radiant mode. The radiation efficiency is 10 to 20 percent higher than that of comparable burners. And if one reduce the excess air (or if one preheat the air to 450 ºC) the burner is even more efficient. The high radiation efficiency makes these burners ideal for drying processes involving infrared radiation, for example.

© Copyright 1990 - Stobbe